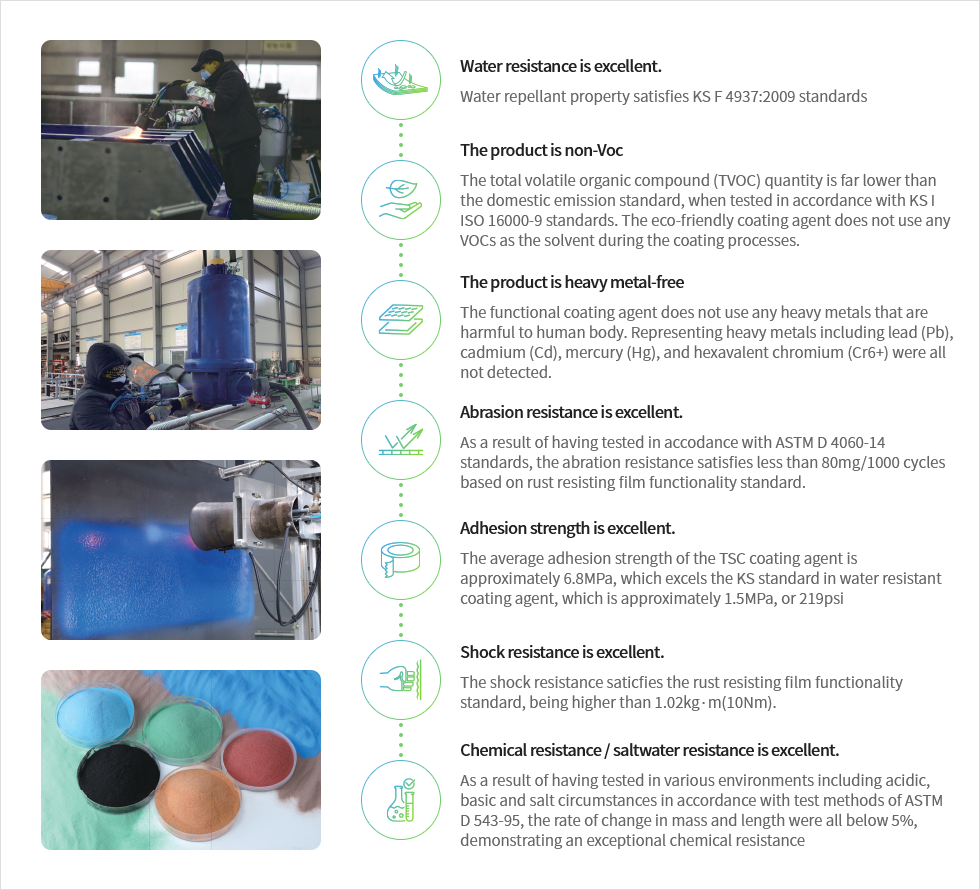

What’s “POLYSCO”? This is a coating agent in which various functional additives are added to polymer resins such as PE and PP, and the coating agent shows exceptional chemical resistance to acids, bases, oils, seawaters and saltwater with the chemical stability of the complex polymer, not to mention being capable of preventing corrosions of various facilities such as iron and concrete. Furthermore, this is a dry-type functional coating developed purely with domestic technology, and this eco-friendly coating agent has solved the problems of the previously complicated and tedious processes, and problems of heavy duty type coating that generates harmful substances from using VOCs as solvents.

| Classification | NO. | Property | Purpose | Chemical resistance |

|---|---|---|---|---|

| General Industry | GI-110 | Abrasion resistance | Various industrial fields such as parking lot, industrial Facility, door warehouse, paint cover | ≤4% |

| GI-120 | Shock resistance | |||

| GI-130 | Tensile strength | |||

| GI-210 | Acid resistance | Chemical industry fields that require chemical resistance, such as environmental plants, chemical plants, water treatment facilities, chemical tanks, and refineries | ≤2% | |

| General Industry | GI-220 | Alkali resistance | ||

| GI-230 | Oil resistance | |||

| General Industry | OL-110 |

Salt water resistance, Microbial resistance |

Salt water coating field such as sluice, shop, and offshore structures |

≤2% (30% Nacl) |

| General Industry | FC-UV-1 | UV resistance | Outdoor use | ≤4% |

| FC-NS-1 | Non-slip | For Non-slip purposes | ≤5% |

* The above colors are printed and mat differ from the actual colors

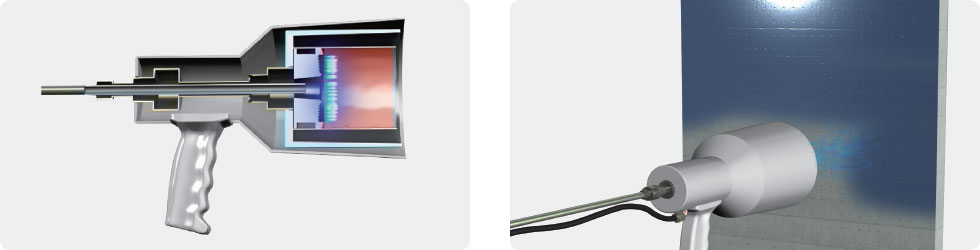

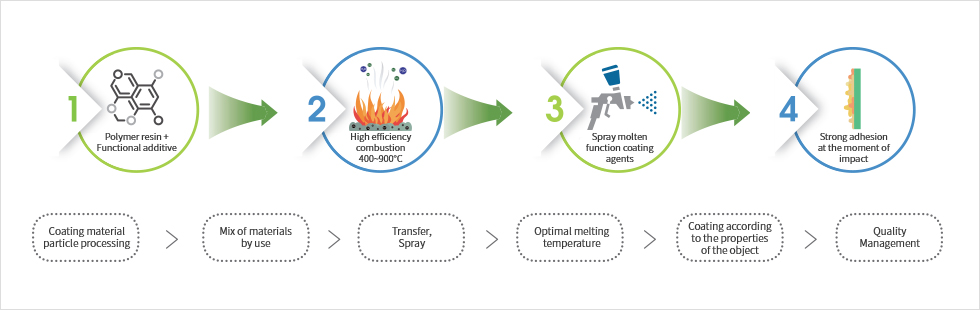

Polymer thermal spray coating is a technology that uses powder thermal spray, in which the heat source is the combustion heat of propane gas, and improves the surface quality by rapidly spraying a powder material into the center of the flame to form a coating film on the basic material.

Unlike the previous oil paints, anticorrosive paints or heavy-duty paints, a volatile organic compound (VOCs), that is, the solvent is not included, used or emitted, and the technology is eco-friendly by using only nontoxic materials and not emitting substances harmful to human body, such as chlorine, dioxin and isocyanate.

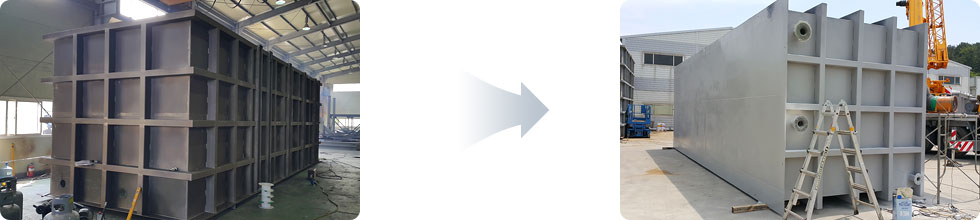

The powdered polymer resin with resistances in heat, chemicals, abrasion and extreme weathers, a coating film is formed on the basic material to protect metal, concrete and industrial materials such as FRP from being corroded or damaged by various seawater, chemicals with strong penetrations such as acid, base and solvents, strong UV ray, water, sand or even moistures.